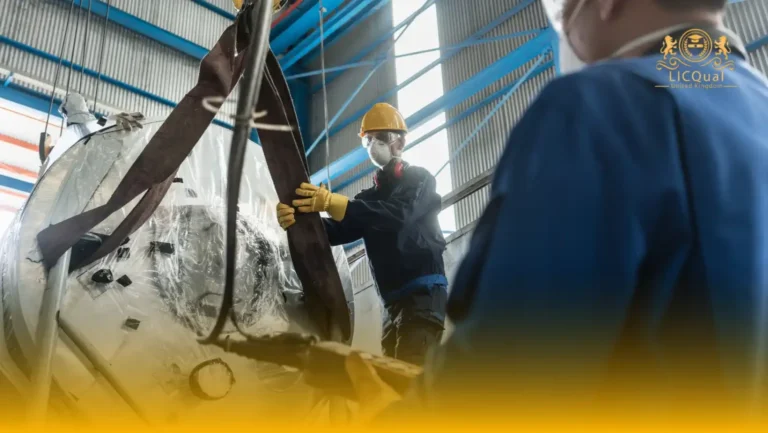

The LICQual Level 3 Diploma in QA/QC Piping Inspector is a globally recognized qualification designed to develop competent professionals in the field of piping inspection, quality assurance (QA), and quality control (QC). This diploma equips learners with the technical expertise and practical skills required to inspect, monitor, and evaluate piping systems used in industries such as oil & gas, petrochemicals, power plants, and infrastructure projects.

This comprehensive program covers critical areas including piping components and layout, welding processes, international codes and standards (ASME, API, ASTM), non-destructive testing (NDT), inspection methodologies, and QA/QC documentation. Learners will gain the knowledge and confidence to perform site inspections, interpret engineering drawings, assess welding quality, and ensure compliance with global standards.

The LICQual Level 3 Diploma is ideal for engineering graduates, diploma holders, site supervisors, NDT professionals, and technicians looking to advance their careers in QA/QC inspection. It also serves as a gateway for individuals aiming to work as certified piping inspectors, quality engineers, or technical auditors in high-demand sectors.

With a focus on hands-on learning and real-world application, this diploma ensures that graduates are job-ready and capable of upholding safety, reliability, and quality in piping systems. Upon successful completion, candidates receive an internationally accredited qualification, enhancing their employability in both local and international markets.

Course Overview

Qualification Title

LICQual Level 3 Diploma in QA/QC Piping Inspector

Total Units

6

Total Credits

60

GLH

240

Qualification #

LICQ2200547

Qualification Specification

To enroll in the LICQual Level 3 Diploma in QA/QC Piping Inspector applicants must meet the following criteria:

|

Qualification# |

Unit Title |

Credits |

GLH |

|---|---|---|---|

|

LICQ2200547-1 |

Fundamentals of Piping Systems and Components |

10 |

40 |

|

LICQ2200547-2 |

International Codes, Standards, and Specifications |

10 |

40 |

|

LICQ2200547-3 |

Welding Processes and Inspection Techniques |

10 |

40 |

|

LICQ2200547-4 |

Non-Destructive Testing (NDT) in Piping Inspection |

10 |

40 |

|

LICQ2200547-5 |

QA/QC Inspection Procedures and Documentation |

10 |

40 |

|

LICQ2200547-6 |

Pressure Testing and Piping Integrity Verification |

10 |

20 |

By the end of this course, applicants will be able to:

1. Fundamentals of Piping Systems and Components

By the end of this unit, learners will be able to:

- Identify and describe various piping system components such as pipes, fittings, flanges, and valves.

- Understand the classification and grading of piping materials based on industrial standards.

- Interpret basic piping drawings, layouts, and isometric diagrams.

- Explain the role of different piping components in system functionality and safety.

2.International Codes, Standards, and Specifications

By the end of this unit, learners will be able to:

- Recognize the purpose and importance of international codes and standards in piping inspection.

- Interpret and apply relevant standards such as ASME, API, ASTM, and ISO.

- Differentiate between various project specifications and understand their application in quality control.

- Ensure compliance with applicable regulatory and contractual requirements.

3. Welding Processes and Inspection Techniques

By the end of this unit, learners will be able to:

- Understand key welding processes including SMAW, GTAW, and GMAW.

- Identify welding symbols, joints, and positions used in piping projects.

- Interpret Welding Procedure Specifications (WPS) and Procedure Qualification Records (PQR).

- Conduct basic visual inspections of welds and recognize common welding defects.

4. Non-Destructive Testing (NDT) in Piping Inspection

By the end of this unit, learners will be able to:

- Explain the principles and methods of common NDT techniques (VT, PT, MT, RT, UT).

- Select appropriate NDT methods based on inspection requirements.

- Interpret NDT results and determine the acceptance or rejection of components.

- Adhere to safety and quality standards during NDT procedures.

5. QA/QC Inspection Procedures and Documentation

By the end of this unit, learners will be able to:

- Develop and follow Inspection Test Plans (ITPs) and quality checklists.

- Maintain accurate and complete inspection records, reports, and logs.

- Document and report non-conformities, and assist in corrective/preventive actions.

- Manage material traceability and ensure proper QA/QC documentation flow.

6. Pressure Testing and Piping Integrity Verification

By the end of this unit, learners will be able to:

- Understand the principles and purpose of hydrostatic and pneumatic pressure testing.

- Prepare piping systems for pressure testing in accordance with safety protocols.

- Monitor and record test procedures and interpret results for integrity verification.

- Identify and report test failures or defects, and suggest corrective actions.

The LICQual Level 3 Diploma in QA/QC Piping Inspector is ideal for individuals who are seeking to build or advance a career in quality assurance and quality control within the piping and industrial sectors. This course is particularly suited for:

- Engineering graduates (Mechanical, Civil, Industrial, Petroleum) who want to specialize in QA/QC inspection.

- Diploma holders and technical trainees looking to enhance their skills in piping inspection and welding quality control.

- Welders, fabricators, and site supervisors aiming to transition into QA/QC roles.

- NDT technicians, piping inspectors, and QA/QC assistants seeking professional growth and certification.

- Professionals working in oil & gas, petrochemical, power generation, or construction industries who need formal training in piping QA/QC.

- Freshers or career changers with a technical background who want to enter the high-demand field of industrial inspection.

This diploma program provides a strong foundation in both theoretical knowledge and practical skills, making it suitable for both entry-level candidates and experienced professionals aiming to strengthen their qualifications and improve job prospects in local and international markets.

Assessment and Verification

All units within this qualification are subject to internal assessment by the approved centre and external verification by LICQual. The qualification follows a criterion-referenced assessment approach, ensuring that learners meet all specified learning outcomes.

To achieve a ‘Pass’ in any unit, learners must provide valid, sufficient, and authentic evidence demonstrating their attainment of all learning outcomes and compliance with the prescribed assessment criteria. The Assessor is responsible for evaluating the evidence and determining whether the learner has successfully met the required standards.

Assessors must maintain a clear and comprehensive audit trail, documenting the basis for their assessment decisions to ensure transparency, consistency, and compliance with quality assurance requirements.